AARADHYA COATING SOLUTION

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to AARADHYA COATING SOLUTION

Powder Coating

Powder coating has a number of benefits, one of which has already been mentioned earlier. Powder coating a metal object allows for a dense sturdy finish, more durable than conventional paints. Secondly, this process only requires a single coat so it is fast, efficient, and easy. In addition to its ease of application, it allows for custom textured and coloured finishes as the powders involved can be nicely manipulated. Furthermore, powder coating objects results in a remarkably even finish as the powder melts and sets across the entire object at once, leaving no application traces or drips. Finally, the powder coating process is environmentally friendly as it produces minimal volatile organic compounds.

Cathode Electro Deposition

Description / Specification of Cathode Electro Deposition

We are involved in offering a wide range of Cathode Electro Deposition to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Cathode Electro Deposition. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

C.E.D. Coating

Cathode Electro Deposition is one of the advanced coating methods used for automobiles and metal equipment. The water based spray ensures smooth, dirt free and precision coating of the object. Apart from being chemically resistant and mechanically durable, the technique is environment friendly. It helps for top coat like spray paint & powder coat.

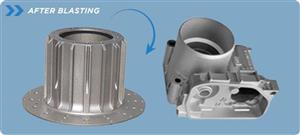

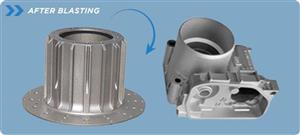

Shot Blasting

Shot Blasting is a surface finishing technique that involves rapidly impacting the surface of an object with a controlled stream of high carbon steel shot material. It is faster and more effective than filing for removing flash that my remain on a part after the casting or stamping process.

Shot Blasting is also used for removing burrs, scale and rust that may interfere with the part's integrity, appearance or definition. Shot blasting can also prepare the surface of a part for coating by removing surface contaminants and provide a surface profile for increased coating adhesion.

Coating Solution

Description / Specification of Coating Solution

We are involved in offering a wide range of Coating Solution to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Coating Solution. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.